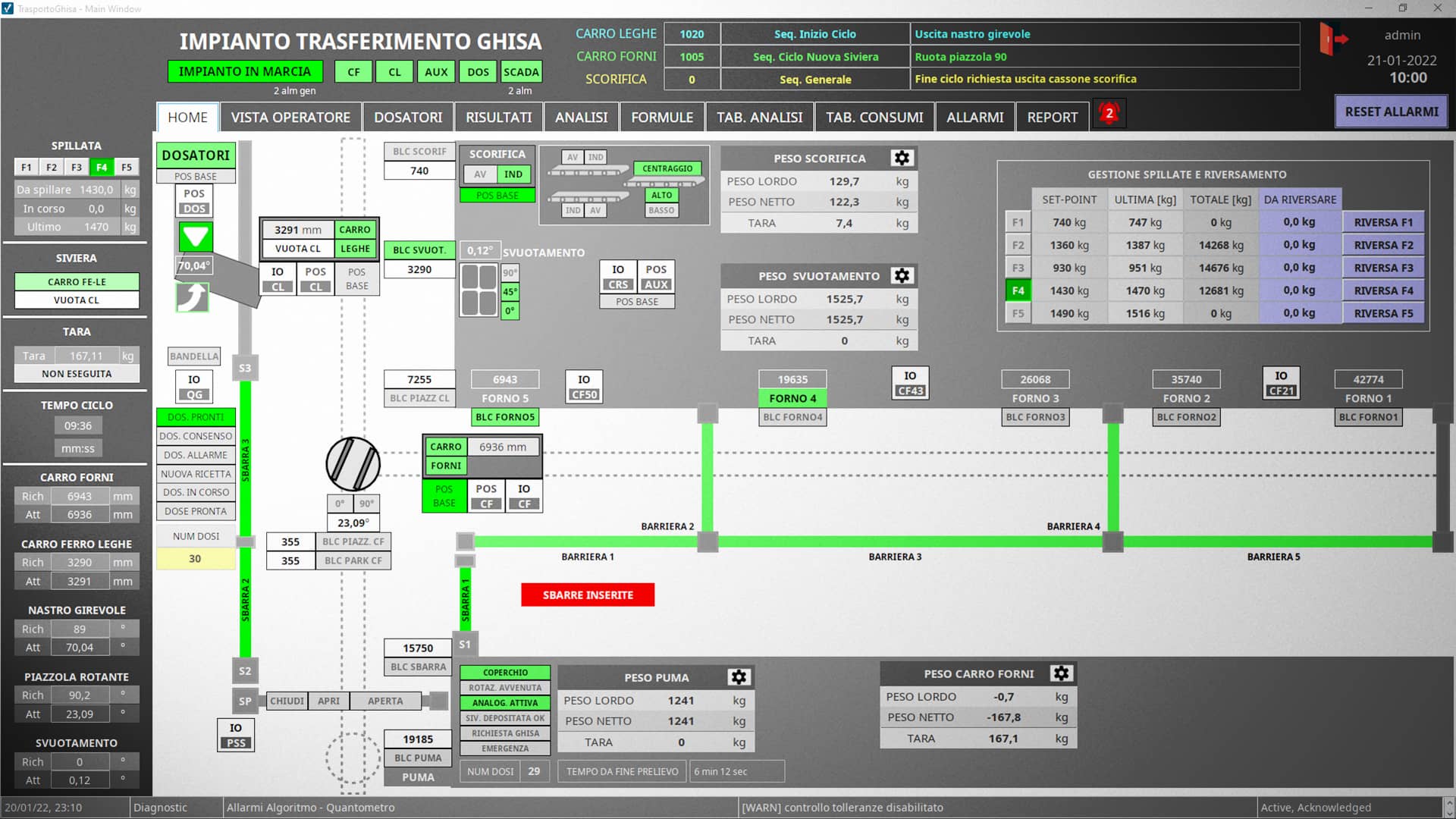

Developed to adapt to the specific needs of each customer and the particularities of their systems. Each plant has unique characteristics and configurations, which vary based on factors such as the type of wood treated, the size of the batches and environmental conditions. For this reason, the software is not a generic solution, but is designed ad hoc, with functions calibrated to individual operational and production needs. During the development phase, the software is configured in close collaboration with the customer, collecting detailed information on process parameters and plant management preferences. This allows you to integrate specific functions, such as the management of customized drying cycles, the possibility of setting control profiles for different types of wood and even the creation of customized automatic reports. The intuitive and customizable interface facilitates the interaction of operators with the system, allowing parameters to be configured according to the specifications of the batch and type of wood, increasing energy efficiency and reducing operating costs. Thanks to the use of advanced algorithms and integration with IoT sensors, the software continuously monitors the state of the system and the condition of the wood, sending data to the central system in real time. This allows dynamic and automated adjustment of drying cycles, minimizing margins of error and ensuring uniform drying that maintains the quality of the wood. Custom software development

Thanks to this customization, the software is able to respond specifically to company needs and optimize the production efficiency of the plant. It not only ensures high performance and consistent results, but also offers management flexibility that allows customers to adapt parameters in real time to changes in production, thus maximizing efficiency and reducing energy consumption and operating costs. characteristics

The specifically designed software guarantees more precise control over parameters such as temperature, humidity and drying time, adapting to the unique characteristics of each type of wood and system.

Furthermore, this type of software allows remote management of the plant, offering detailed reports and real-time analysis to help managers make quick and informed decisions.

This website uses cookies to improve your web experience.